The industrial manufacturing sector is reaching new stages of AI maturity. As of 2025, 51% of companies already use some form of AI in their operations, and 61% expect to increase AI investment by 2027. Some of that spending has already gone to developing industrial foundation models for co-piloting industrial processes.

But there’s also a growing trend of investing in on-device AI for industrial assets. As data fragmentation remains high among different on-site assets and the cloud introduces unwanted latency, leaders are looking for ways to run data analytics on the edge.

In this post, we explore where embedded AI is creating the strongest, most immediate value — and how forward-thinking industrial companies are turning on-device intelligence into measurable operational gains.

What is Embedded AI?

Embedded AI (also called on-device AI) embeds machine learning directly into industrial assets such as machinery, HVAC systems, sensor networks, and various vision systems. Instead of relying on cloud systems, AI algorithms run locally on the device itself. This allows production assets to interpret their own data, adjust to changing conditions, and respond in real time.

The benefits of embedded AI are often summarized with the BLERP acronym, coined by Jeff Bier, Founder of the Edge AI and Vision Alliance:

- Reduced Bandwidth. As raw sensor data remains on the device, fewer networking resources are required.

- Lower Latency. Edge inference avoids the long detours to the cloud and removes lags that could disrupt production.

- Better Energy Efficiency. Edge devices require fewer resources than virtualized or containerized cloud environments.

- Higher Reliability. Models remain functional even when central connectivity drops, which is common at remote sites.

- Improved Data Privacy. Sensitive industrial data remains on-device, within the controlled security perimeter.

For manufacturers, the above translates to greater production speeds and decision autonomy. Embedded AI systems can monitor vibration, temperature, and pressure patterns in industrial heat exchanges and alert about early signs of failure. Vision-based quality control inspection systems can draw attention to micro-defects on production lines to improve first-pass yield. Power-intensive equipment can automatically shift into lower-consumption modes during idle cycles, reducing unnecessary energy draw. The possibilities for building learner processes are ample!

That said, embedded AI also has some inherent limitations:

- Limited computational power. Higher range silicon on chip (SoC) devices can muster about 6 to 12 trillion of operations per second (TOPs). But smaller edge processors have lower throughput. Meaning larger AI models will have to be optimized for available resources.

- Complicated remote access. Cloud enables easier access to model outputs from literary any device. Edge devices require more intricate network configuration setup for easy access and ongoing maintenance.

- Scalability bottlenecks. With almost limitless cloud resources, you can easily add extra resources for effective model serving. Edge computing, on the contrary, can only be scaled via extra hardware purchases.

Still, embedded AI in manufacturing can drive massive shifts in how companies maintain equipment, ensure product quality (and workers’ safety), and use the available resources.

Why Invest in Embedded Edge AI?

Gartner expects edge computing adoption to rise from 20% today to 50% by 2029, with most deployments running some form of AI. Revenue from dedicated AI processors is also projected to reach $137 billion by 2027.

These numbers indicate that leaders are eager to adopt architectures that interpret data at the source, not in transit. By empowering machines to interpret their own signals in the moment, industrial companies can create difficult value opportunities (if not impossible) to achieve through cloud-only architectures. For example:

- Implement real-time adjustments to running process parameters to improve yield or optimize process scheduling

- Reduce unplanned downtime costs with predictive alerts about increasing tool wear or performance degradation

- Decrease defect rates with on-device vision systems that auto-flag specification deviations in milliseconds

- Ensure better employee safety through enforced PPE compliance and contextual task assistance

- Launch a connected aftermarket ecosystem for new equipment that extends the product lifecycle and deepens post-sale engagement.

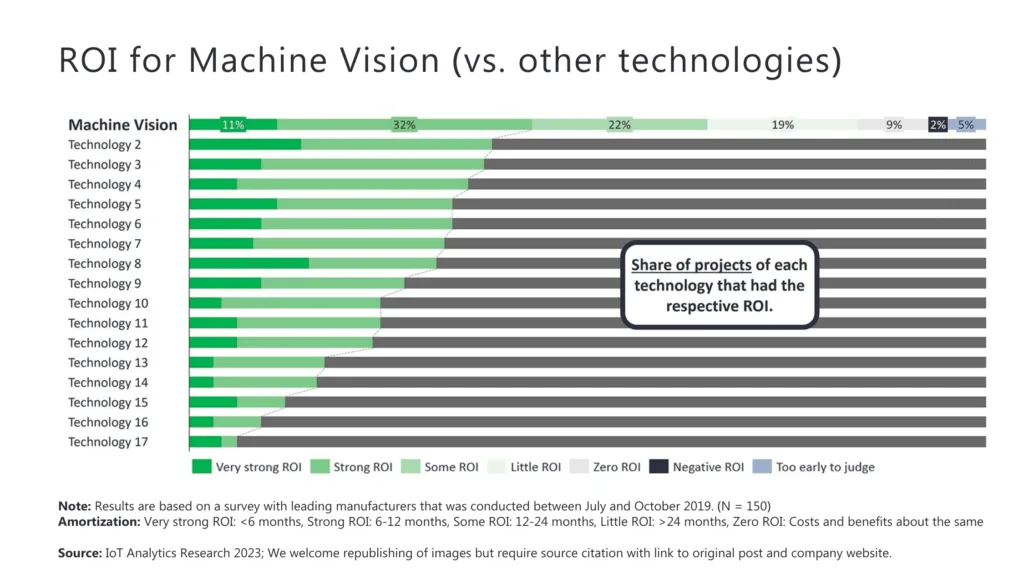

These aren’t abstract benefits. Embedded edge AI has a particularly compelling payback horizon. Machine vision had the highest ROI and quickest amortization time of all Industry 4.0 technologies.

Source: IoT Analytics

McKinsey Research also reports that industrial processing plants that adopted AI report 10-15% increases in production and a 4-5% increase in EBITA, mostly though:

- Faster incident response times that prevent costly defects or outages

- Higher equipment uptime and longer component lifespan

- Lower energy bills through dynamic load management

- Improved throughput from smarter process control

- Reduced labor burden thanks to automated inspections and monitoring

With profit margins being constantly squeezed, embedded AI can bring meaningful, measurable returns with minimal re-architecture of the existing technology stack. And several leaders are already capitalizing on this fact.

Key Embedded AI Opportunities For Industrial Manufacturers

Manufacturers are actively experimenting with embedded AI use cases that cloud-only systems can’t deliver. In particular, most are turning to edge systems to improve uptime, quality, safety, and resource efficiency.

The cases below show how early adopters translate embedded AI into measurable performance advantages across their production environments.

Remote Process Monitoring

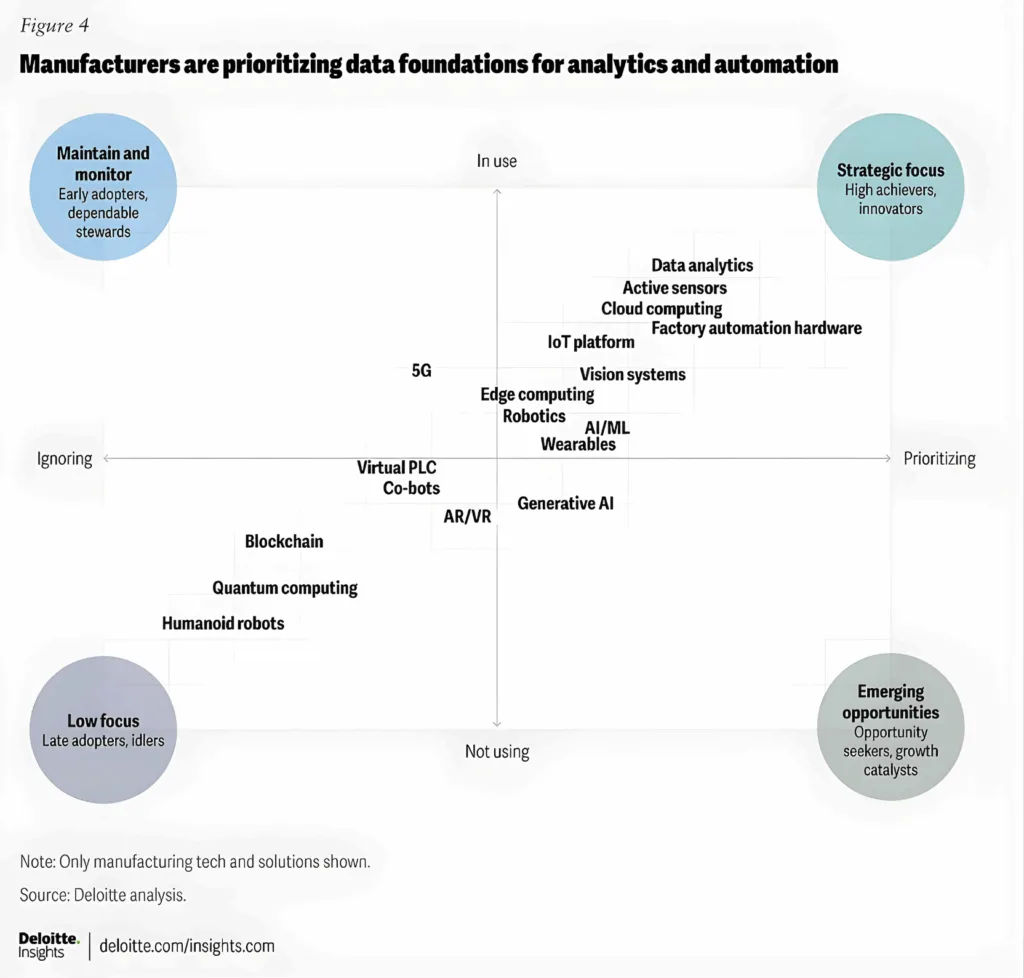

Manufacturers have long relied on periodic inspections and operator experience to decipher what was happening on the production floor. That’s changing as manufacturers accelerate investments in data analytics, active sensoring, IoT platforms, and factory automation software.

Source: Deloitte

The majority (92%) of industrial leaders see these investments as a cornerstone for ensuring competitiveness over the next three years. In particular, through higher operational efficiencies and elevated product quality.

Scaled IoT deployments, robust data processing infrastructure, and embedded AI enable more advanced remote monitoring scenarios.

Instead of relying on local, manual supervision, manufacturers can observe entire production systems across sites, lines, or continents in real time. Edge AI handles immediate interpretation of sensor signals and triggers responses on the device itself. Cloud AI aggregates data across multiple facilities, producing higher-level insights on efficiency, quality, or risk. Many leaders are formalizing this model through Remote Operations Centers (ROCs) — centralized hubs where engineers oversee distributed plants through AI-generated dashboards that highlight the most urgent issues.

Edvantis engineering team has recently helped a global energy control manufacturer progress in this direction. Our team has modernized a legacy Remote Panel application, deployed across 40 plants, enabling better integration with modern hardware and support platforms. The new system, based on the VNC (Virtual Network Computing) protocol, has a more intuitive design and offers better visualizations for system monitoring, power management, and remote control.

And the next step for the company may be progressing towards an edge AI algorithm deployment, like some leaders in the space are already doing.

Siemens and the Armv9 Edge AI Platform

Siemens is one of the companies exploring how on-device intelligence can transform remote oversight. Using Arm’s latest Armv9-based edge AI platform — equipped with the Cortex-A320 CPU and Ethos-U85 NPU — Siemens can deploy AI models with more than one billion parameters directly on factory equipment. The platform dramatically improves inference performance and reduces reliance on cloud connectivity, enabling machines to react in milliseconds instead of waiting for off-site systems.

When the system detects drift in performance, it recalibrates settings automatically. The effect is a production line that self-corrects, minimizes scrap, and improves with every cycle — all monitored remotely by engineers who no longer need to be physically present at the line.

Micron Technology’s Multi-Sensory Edge Monitoring System

Micron Technology offers a different view of what remote monitoring looks like when the process is exceptionally complex. Its semiconductor manufacturing workflows involve as many as 1,500 tightly controlled steps. Even a small defect — a scratch on a wafer, a bubble under protective film — can disrupt production at a cost of up to $250,000 per hour.

To reduce these risks, Micron built an advanced edge monitoring system that merges data from thousands of sensors and imaging devices. Petabytes of information flow from more than 8,000 sources across global facilities into a unified data environment, used for training AI models.

Micron’s AI-Auto-Defect Classification (ADC) system uses deep learning to identify and categorize millions of wafer defects. The company also uses auditory sensors to detect acoustic anomalies in robotic actuators. AI converts these sounds into visual graphs and alerts teams when unfamiliar frequencies appear, often pinpointing the root cause. Thermal imaging adds another layer: infrared heat maps compared against digital twins allow AI to spot temperature inconsistencies long before equipment fails.

Operational Safety Monitoring

Factory floors remain a hazardous work environment. Last year alone, heavy machinery operators in the US sustained about 18,000 serious injuries, including amputations, lacerations, crushing accidents, and abrasions.

In many cases, incidents occur due to fatigue, misjudgment, or lack of experience — and traditional safety protocols alone cannot prevent them.

Embedded AI can extend an extra layer of protection over your workforce. Camera-based vision systems can scan for visual cues indicating risk factors. For example, flag if the worker is missing required PPE, stepping too close to a moving machine, or walking into a forklift lane. They can identify spills, misplaced tools, and blocked exits. Unlike human observers, industrial algorithms never tire, never look away, and never miss a frame.

For instance, Arcure’s Blaxtair perception technology, embedded in industrial vehicles, can detect pedestrians in real-time, guide vehicles safely around obstacles, and generate detailed 4D depth maps to improve driver awareness.

Surveily’s AI-powered safety monitoring system, in turn, combines personal protective equipment (PPE) monitoring with high-risk incident tracking. A steel mill recently deployed it to oversee multiple layers of safety:

- Advanced Zone Safety Detection: Cameras tracked hazardous areas continuously and issued alerts when workers entered unsafe zones, including crane operating paths.

- PPE Compliance Enforcement: Non-compliance was identified instantly and flagged for correction.

- Truck Wheel Blockade Monitoring: AI verified that wheel chocks were properly engaged, avoiding accidental vehicle roll.

- Real-Time Notifications: Supervisors received immediate alerts via dashboard and mobile notifications.

- Automated Reporting: Weekly and monthly incident summaries helped the safety team target recurring patterns.

- Scalable Integration: The platform worked alongside the mill’s existing infrastructure, minimizing disruption to operations.

The impact was clear and measurable:

- 92% reduction in near-traverse alerts

- 90% reduction in total safety violations

- 73% reduction in PPE non-compliance

These results demonstrate how embedded AI can transform the safety profile of even the most demanding industrial environments. When machines can interpret their surroundings and elevate risk signals instantly, safety becomes proactive rather than reactive. And in sectors where a single misstep can carry life-altering consequences, this shift is nothing short of essential.

Optimized Energy Management

Industrial energy systems are among the most intricate components of manufacturing operations. Equipment usage patterns fluctuate throughout the day. And so do utility tariffs. And with the upcoming renewable energy integration in the grid, energy supply and pricing can become even more dynamic.

Human operators can manage only a fraction of this complexity in real time. AI, in contrast, can comb through thousands of signals simultaneously to adjust energy use. This AI-enabled approach to energy management is often referred to as demand response. And it’s becoming far more practical now that edge and cloud AI can coordinate scheduling autonomously.

Successful deployments show that smarter forecasting and load shifting can dramatically reduce peak power charges and deliver ROI within just 12 months.

Renault: AI for Predictive Energy and Cost Reduction

In 2023, Renault reported €270 million in combined energy and maintenance savings, gained from AI-driven predictive maintenance tools across its industrial sites. The company uses over 300 AI applications today — tracing parts, enhancing production quality, and managing energy consumption with increasing sophistication.

Through its AI-powered Ecogy portal, Renault can monitor energy use across facilities in real time and react immediately to deviations. This predictive approach reduced site-level energy demand by 20% and is part of a broader ambition to cut consumption by 40% by the end of 2025. The company plans to expand its AI portfolio to 3,000 applications mid-decade, with the goal of reducing EV manufacturing costs by half by 2027.

Schneider Electric EcoStruxure™ Advisor

Schneider Electric’s work at a semiconductor plant illustrates another dimension of this opportunity. Using its EcoStruxure™ Advisor, Schneider deployed an AI system capable of analyzing every major utility source — boilers, chillers, compressors, and air handlers. The platform continuously fine-tunes settings to maintain ideal operating conditions with minimal energy use.

The results were striking:

- $1 million in annual energy cost savings

- 10,000 tons of CO₂ emissions, reduced each year

- A payback period of under six months

- No negative impact on production throughput

The embedded AI algorithms uncovered efficiencies operators had missed, from optimizing load distribution to shutting off equipment left idling between shifts.

Equipment and Tool Wear Monitoring

Among the most established applications of embedded AI in manufacturing is condition monitoring — the continuous assessment of machine health through sensor data and machine learning.

This capability has fundamentally changed how factories handle equipment wear. By detecting early signs of stress, degradation, and improper operating conditions, manufacturers can intervene before failure occurs, rather than reacting to breakdowns.

Embedded AI algorithms can process multiple parameters — vibration levels, spindle currents, acoustic patterns, temperature profiles — to build normal asset behavior signatures. So when there’s a subtle shift in a cutting tool’s vibration, a spike in motor current, or a pattern associated with overheating, the model can quickly alert the operator and recommend possible remedies.

Such predictive insights reduce downtime, lower maintenance costs, and extend equipment lifespan, while also strengthening worker safety. These gains are not theoretical. Many manufacturers already rely heavily on embedded AI for tool and equipment monitoring.

THK’s AI System for Cutting Tool Health

Japanese manufacturer THK developed a specialized AI solution to monitor cutting tool conditions — a critical need in facilities where even small defects can trigger rework, scrap, or machine damage. Cutting tools chip, dull, or fracture unpredictably, and their replacement costs add up quickly.

THK’s system solves this with a simple retrofit. A sensor is clamped onto the machine tool’s motor cables, with no need for a CNC connection or major reconfiguration. Installation takes minutes. Once in place, the AI automatically analyzes waveform data, comparing it with historical cutting tool replacement patterns. When it detects the signature of a chipped or failing tool, it sends an instant alert.

For factories running automated lines, this can be the difference between stopping a process immediately or discovering thousands of defective parts the next morning. The system’s simplicity — no complex software configuration, tablet-based setup — makes adoption fast and cost-effective.

GE Aerospace: AI for Real-Time Engine Component Monitoring

GE Aerospace extends the impact of embedded AI into one of the world’s most safety-critical domains. The company uses an AI-enabled Blade Inspection Tool to assess turbine blades for narrowbody aircraft engines. Technicians capture detailed images, and the AI guides them to the frames most likely to reveal defects. This cuts inspection time in half, to about 1.5 hours, and improves consistency across teams.

Across GE’s commercial engine fleet, AI monitors conditions 24/7. Thanks to algorithms, GE can detect potential malfunctions 60% earlier with 45% higher accuracy. These insights enable preventive action well before components reach critical thresholds.

The results mirror broader industry outcomes: manufacturers using AI-based predictive maintenance report an average 28% improvement in equipment uptime and a 30% reduction in maintenance costs.

Robots and Cobots

The new generation of industrial robots tout advanced machine vision, real-time path planning, and learning algorithms, courtesy of recent advances in AI models (e.g., Gemini Robotics, NVIDIA’s Isaac GR00T N1, or Helix VLA model) that can be deployed on the edge.

AI-enhanced robots are powered by a constellation of sensors — cameras, force-torque sensors, LiDAR, depth sensors, and microphones — to understand their environment better.

Embedded algorithms interpret those signals in real time, allowing robots to identify objects, classify materials, and judge how best to approach a task.

Vision-guided arms can handle complex picks without predefined coordinates. Cobots adjust their speed or force when a human approaches, maintaining productivity without compromising safety. For manufacturers, this means automation that no longer requires months of planning or specialized robotic expertise. It can evolve with production needs, as the following cases illustrate.

Xiamen Runner’s Rapid Cobot Deployment

Xiamen Runner Industrial Corporation demonstrates how transformative collaborative robots can be. The company recently deployed 64 Universal Robots cobots across ten applications, ranging from injection molding to machine tending, gas testing, and assembly. Before this shift, production relied heavily on manual labor that left operators fatigued and exposed to repetitive, sometimes unsafe tasks. Variability in output was a constant challenge.

The introduction of cobots changed that equation. Production times dropped, product consistency improved, and overall line reliability increased. What’s notable is the implementation speed: new cobot projects now go from concept to deployment in one week, compared to the six-month timelines associated with traditional industrial robots.

This agility enables Xiamen to recalibrate production rapidly — a crucial advantage in markets where product lifecycles continue to shorten.

BMW’s Exploration of Humanoid Robotics

BMW is taking automation further by piloting humanoid robots at its Spartanburg plant. The latest Figure 02 robot from California-based Figure successfully performed a delicate body-shop task: inserting sheet metal parts into precise fixtures before assembly. The step requires tactile sensitivity, positional accuracy, and the ability to adapt to slight variances — capabilities that until recently belonged exclusively to skilled human workers.

Humanoid robots are still in early deployment, but BMW’s experiment signals where advanced automation could be heading: robots that can navigate human-designed environments without major retooling, and take on tasks that blend strength, dexterity, and spatial reasoning.

Conclusion

Embedded AI is proving to be a practical path to higher machinery uptime, safer operations, and smarter resource usage. The companies, already experimenting with edge AI model deployment, report strong ROI, especially in the areas of remote equipment monitoring, safety automation, and tool-wear prediction.

If you’re looking for ways to embed AI into the production fabric, Edvantis would be happy to help. Our engineering teams bring the business domain knowledge and practical experiences in integrating new sensors, building edge-ready AI models, and modernizing legacy systems. If you’re exploring where embedded intelligence can create the strongest impact in your operations, let’s build the roadmap — and the results — together. Contact us.