The demand for wind power is on the rise year on year, and so is the supply. In 2023, global wind generation grew to 216 TWh (up 10%) — the highest among all renewables. But even that isn’t enough to hit the Net Zero Emissions by 2050 targets.

While expanding installed capacity is essential, building more wind farms alone won’t bridge the gap in supply vs demand. Operators continue to face revenue-eroding issues like unscheduled downtime, high asset servicing costs, and grid integration challenges — all leading to revenue volatility.

By taking advantage of emerging digital technologies, wind farm operators can move from basic inspection and scheduled servicing to proactive, data‑driven operations that optimize capacity factors, extend asset lifecycles, and improve revenue stability.

4 Ways Digital Technologies are Changing Wind Farm Management for The Better

Keeping a wind farm profitable is tough. Between unpredictable wind patterns, rising O&M costs, and volatile energy markets, even small inefficiencies can cost you a lot. Large players had to settle for an EBIT margin of 4% to 5% on average. In many cases, the paths to performance optimization remain anything but obvious, as many operators still rely on outdated tools and incomplete data.

But there’s a better way. Emerging digital technologies in the energy sector are giving wind farms the same precision and predictive power as a high-tech trading floor, helping operators make smarter calls on where to build, when to service, how to bid, and how to get more out of every turbine in the field.

Multi-Criteria GIS Modeling for Site Selection and Farm Layout Optimization

When it comes to location selection, wind resource quality (aka speed and density) is the prime profit driver. But other less-obvious factors are in play too. High average wind speeds might mean nothing if grid access is too costly or environmental constraints slow development. Likewise, factors like road density, land type, and population density also significantly impacted the payback period for wind farms, according to a recent study.

Thanks to recent advances in big data analytics, wind farm operators can now run more advanced planning scenarios, using multi-criteria GIS modeling techniques.

Here’s how GIS-MCDM analysis works:

- GIS layers: You can collect spatial datasets covering wind resource quality, grid lines, roads, elevation, land use, and environmental constraints like bird migration corridors for targeted areas.

- Multi-Criteria Decision-Making (MCDM) methods: Next, you can apply decision-making frameworks like AHP, Fuzzy-AHP, TOPSIS, ANP, or OWA that assign weights to each factor based on expert input or pre-programmed analytical rules.

- Advanced optimization routines: Lastly, add algorithms such as genetic searches or reinforcement learning to rapidly test thousands of layout scenarios that balance output, cost, and impact to find that ‘sweet spot’.

The government of Jamaica recently did a national GIS-MCDM modeling study to identify optimal wind zones, modeling factors from wind speed to population density. Results revealed a potential capacity boost of 8.99% beyond the country’s existing 99 MW, particularly in parishes like Westmoreland and Clarendon — a valuable step toward Jamaica’s 50% renewable energy target by 2030.

In Western Turkey, researchers also used the GIS-MCDM approach to figure out new onshore sites. In this case, they also added CO₂ emissions from turbine component transport into the evaluation criteria. Surprisingly, areas near İzmir, with slightly lower wind speeds, outperformed Istanbul and Çanakkale on lifecycle emissions, achieving as low as 7.14 g CO₂-eq/kWh.

The big boon of GIS-MCDM is that it transforms scattered, complex datasets into clear suitability maps for new wind farm sites. Developers gain:

- A ranked shortlist of areas that maximize yield and minimize costs

- Visualized trade-offs across alternative site scenarios

- Data-backed decisions that improve NPV, IRR, and payback periods

By using this method at the early planning stage, you can reduce risk, streamline permitting, and lock in higher long-term profitability before a single foundation is laid.

Predictive Maintenance Systems For Leaner OPEX

For wind farm operators, the real revenue is downtime. Operation and maintenance (O&M) costs can consume about 40% of total OPEX, rising even higher for offshore installations or larger, next-generation turbines.

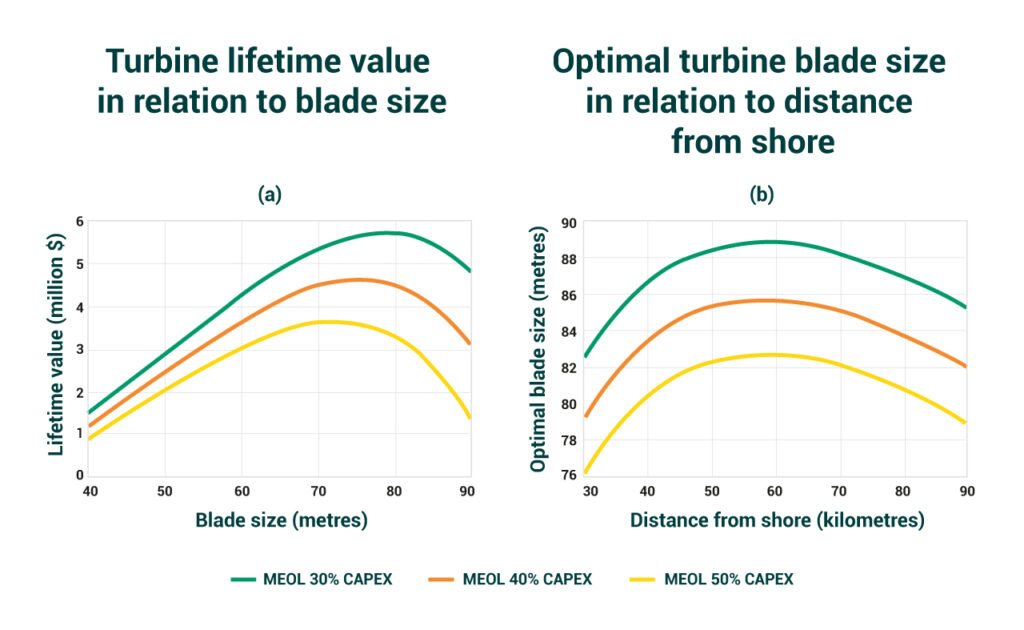

While bigger blades and more remote locations may seem like a logical path to higher yields, research tells a different story. An INSEAD study found an inverse U-shaped relationship between profit, turbine size, and distance from shore: beyond an optimal point, the gains taper off as maintenance and end-of-life costs outweigh performance benefits. Siemens Energy’s recent $2.4 billion bill for defect-related turbine repairs is a stark reminder of what’s at stake.

Predictive maintenance can help shift the O&M economics. Pre-trained machine models can parse structured and unstructured data from sensors, weather stations, performance logs, and other connected data sources and predict anomalies before they become costly nuisances. With this foresight, operators can service turbines at precisely the right moment, avoiding unnecessary interventions while preventing revenue-draining outages.

For turbine manufacturer Suzlon, predictive analytics became a $35 million advantage. Their system, trained on operational and failure data, was able to forecast 83% of gearbox failures up to 45 days in advance. Deployed across more than 700 turbines, it sharply reduced both repair costs and downtime. Similarly, AES Corporation combined physics-based modeling with AI in the H2O AI Cloud to build highly accurate failure prediction models for dozens of turbine components. Initial deployments saved costs and stabilized output so effectively that the company scaled to 35 models in production, expanded sensor coverage, and even automated oil sampling.

What often stands in the way of greater operational foresight are legacy technologies, from outdated SCADA systems with limited data granularity to aging PLCs and proprietary turbine controllers that can’t integrate with modern analytics or IoT sensors. Edvantis has recently helped a Danish wind farm operator solve these exact problems. We upgraded the legacy Real-Time Operating System (RTOS) to support next-generation embedded controllers, built with ARM Cortex architecture. This has allowed the team to integrate operational data from next-gen sensors to measure wind speed, temperature, and humidity. Then feed this data directly into the turbine’s control system to enable dynamic operational adjustments and automated safety measures like alarm notifications and rapid shutdowns.

The bottom line? Predictive maintenance can drastically cut O&M bills. With early issue detection, just-in-time servicing, and optimized scheduling, downtime can be reduced without sacrificing asset lifecycles to keep a healthy profit margin.

Machine Learning for Sharper Energy Bidding Strategies

Selling wind power is as much a forecasting challenge as it is an engineering one. Output can swing with the weather, making it difficult to predict day-ahead prices or balance costs with precision. In many European energy markets operating under a one-price system, this volatility tempts operators into “all-or-nothing” bids, committing their full capacity or holding back entirely. While rational in the moment, this collective behavior can backfire if imbalanced prices shift unfavorably, eroding profits over time.

The stakes rise even higher for hybrid operations that pair wind farms with battery storage or flexible plants. Deciding whether to store energy, sell immediately, or hedge against forecast errors becomes a multi-layered puzzle involving spot, balancing, and ancillary service markets. Traditional bidding models often struggle to react to shifts fast enough.

Machine learning, and particularly reinforcement learning (RL), offers wind farm operators access to smarter bidding strategies, backed by both historical patterns and real-time market signals.

One research team developed a deep RL-based joint-market bidding strategy for a co-located wind-battery system, breaking the problem into two interlinked decision processes — one for the battery, one for the wind farm. This allowed the system to absorb curtailed wind output while bidding strategically across markets. Using real-world wind data, the model increased operational revenues by about 25% and reduced wind curtailment by more than double compared to traditional benchmarks. Charging the battery with otherwise wasted wind generation created further gains.

Another group pushed the concept further with a multi-agent deep RL system that combined the Black–Scholes model with a Hamiltonian function to balance short-term bidding efficiency against long-term positioning. By separately optimizing transaction volumes and prices, it avoided internal trade-offs and captured complex market dependencies through advanced spatiotemporal modeling. Tested on real transaction data from China’s Shanxi electricity market, it significantly outperformed conventional risk-averse strategies, delivering both higher profitability and better price-risk management.

In other words: machine learning transforms energy bidding from a reactive gamble into a calculated, data-driven strategy — one that maximizes revenues and protects margins in the face of price swings and operational uncertainty.

Digital Twins For Day-to-Day Operational Improvements

Running a wind farm well means making thousands of small operational decisions — the kind that add up to significant gains (or losses) over time. But many operators make these calls with limited, incomplete, or outdated data, as most of it remains trapped across multiple operating systems.

Digital twins (DTs) aim to facilitate greater data integration by providing a dynamic, virtual replica of the wind farm, continuously updated with real-time data from IoT sensors, controllers, monitoring systems, and historical logs.

With a digital twin, you can simulate “what if” scenarios based on real-world data. For example, adjust blade angles, test new control strategies, or analyze the root cause of anomalies remotely — actions that traditionally can have costly consequences when executed on real-world assets.

The results of such modeling can be substantial. In one project led by KPMG, a wind farm operator used digital twin modeling to fine-tune both blade angles and nacelle orientation. These adjustments improved turbine performance by up to 2.9%, drawing in €9,300 in extra annual revenue per turbine. Applied across 200 turbines, this meant an additional 32,000 MWh of electricity (worth as much as €2.2 million) without adding new capacity.

MIT researchers achieved similar results with a flow control model embedded into a digital twin environment. By predicting optimal yaw misalignment angles within ±5 degrees for most wind directions, they increased energy production by 2.7% in targeted conditions and 1.0% across all wind speeds in a multi-month experiment. Their validated model now offers a blueprint for collective wind farm operation, where turbines are adjusted in coordination rather than isolation.

The HIPERWIND project (shorthand for Highly advanced Probabilistic design and Enhanced Reliability), in turn, works on improving levelized energy costs at offshore installations. Their pilot project at an offshore wind farm off the coast of England achieved a 9% cost reduction through advanced modeling and quantification of uncertainties related to turbine tower and foundation design.

With the right data and modeling capabilities, wind farm management becomes a precision exercise, not gut-guessing. Operators can test (and then execute) multiple strategies to unlock revenue gains that traditional O&M approaches often leave on the table.

Conclusion

The global demand for wind energy won’t be sated by capacity expansion alone. We’ll have to focus on improving operating efficiencies, too. By embedding more digital technologies into different stages of the wind farm lifecycle — from site selection and construction to real-time market participation and day-to-day performance tuning — operators are already seeing substantial gains in capacity factors, cost efficiency, and revenue stability.

Edvantis can help you take your wind farm operations to the next stage. We partner with energy companies on implementing advanced analytics, IoT, and AI solutions that deliver tangible performance improvements. Let’s talk about how we can turn your wind farm into a high-output, high-profit operation.